Alongside every innovation, there is a fascinating history and story to tell. This is also true for the process of plastic injection molding. In many manufacturing and production methods, injection molding is a solution that helps develop parts and models in a range of applications. Let’s look at the telling history of this process and see what the future looks like.

The Early Days

With its inception occurring back in 1872, injection molding is a long-standing practice that had a large hand in how society evolved with production machinery. The inventors of the first patented injection machine were John and Isaiah Hyatt, and they used the original machine to mold combs, buttons, and similar objects. This process marked the beginning of the plastics engineering industry with much success.

This original piece of equipment was relatively simple in design. It wasn’t long before scientists in Germany began to simplify the process even further. They created a solution with reduced flammability, which included the development of soluble structures of cellulose acetate.

Progression Through WWII

The 1930s were a particularly rough period across the globe. But in the way of inventions, this period saw exponential growth in the plastics industry with the invention and use of thermoplastics like polyolefins, polystyrene, and polyvinyl chloride. As consumer demands evolved through adversity, initiatives such as automotive technology, war manufacturing, and aircraft production saw growth and new heights.

Because of the drastic effects of the war, many industrial materials, like rubber, brought about creative and cost-effective solutions. The most affordable alternate was plastic. Because of how affordable it was and still is, plastic injection molding played a significant role during the post-war period of industrial revolutionization.

What Happened Next?

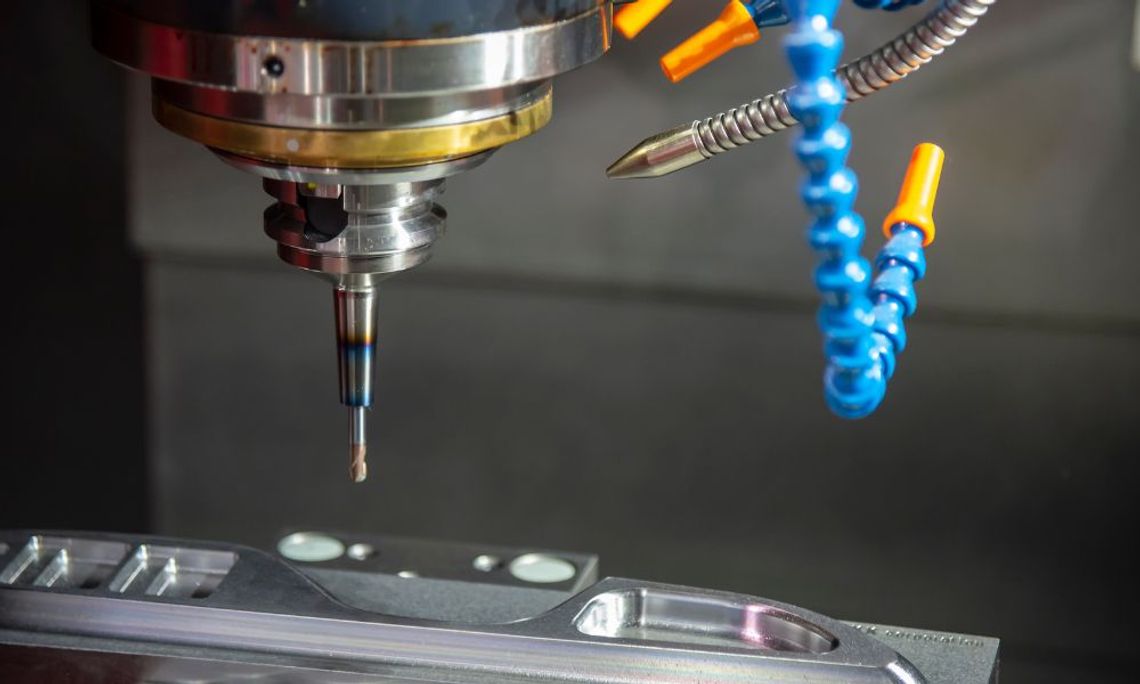

The next critical segment of plastic injection molding came with the invention of extrusion screw injection equipment. With this breakthrough, the quality of plastic products saw a significant increase.

This process opened doors for creating complex, hollow, or larger plastic products. Plastic started to replace steel production in many industries because of affordability, design, and production rates.

A Look at The Future

So what comes next for plastics production? The process of plastic injection molding is used in many of today’s modern industrial needs and boasts a wide range of benefits, including dependability, resiliency, and cost-effectiveness. Additionally, this process now includes advancements in technology and computerized interventions.

Many expect this production process to stick around for a while, but as for how it evolves, technology is paving the way. Perhaps an increase in technology opens the door to higher production rates and decreased downtimes in overall mechanisms. History would suggest plastic injection molding processes thrive under pressure, and consumer convenience only progresses these efforts even more.

Comment

Comments