Having a functional backup generator safeguards against power outages that can cause a domino effect of detrimental consequences. But what happens if backup power units run into failures during times of need?

Here are five reasons your commercial generator is failing and possible solutions to get things up and running.

Battery Failure

A top reason for commercial generator failure is deterioration due to loose and dirty connections. Your generator can also experience a misstep due to sulfation buildup on the battery's plates.

When sulfate builds up on a battery, the part can't deliver a robust current to power the backup energy supply and corrode surrounding components. Consider conducting routine maintenance to maintain battery performance.

Circuit Breaker Issues

Batteries can also fail due to circuit breaker issues. As part of your maintenance checklist, check your circuit breaker trip settings to ensure they match your commercial generator's load system. Adjust settings according to each new installation or load change.

Low Coolant Levels

Low coolant levels can happen when leaks within or outside the unit develop. Keep a vigilant eye out for puddles during inspections; coolant colors can vary from red and orange to green and blue, depending on its manufacturer. Remember to also inspect the oil for a milky appearance and abnormalities.

Overheating

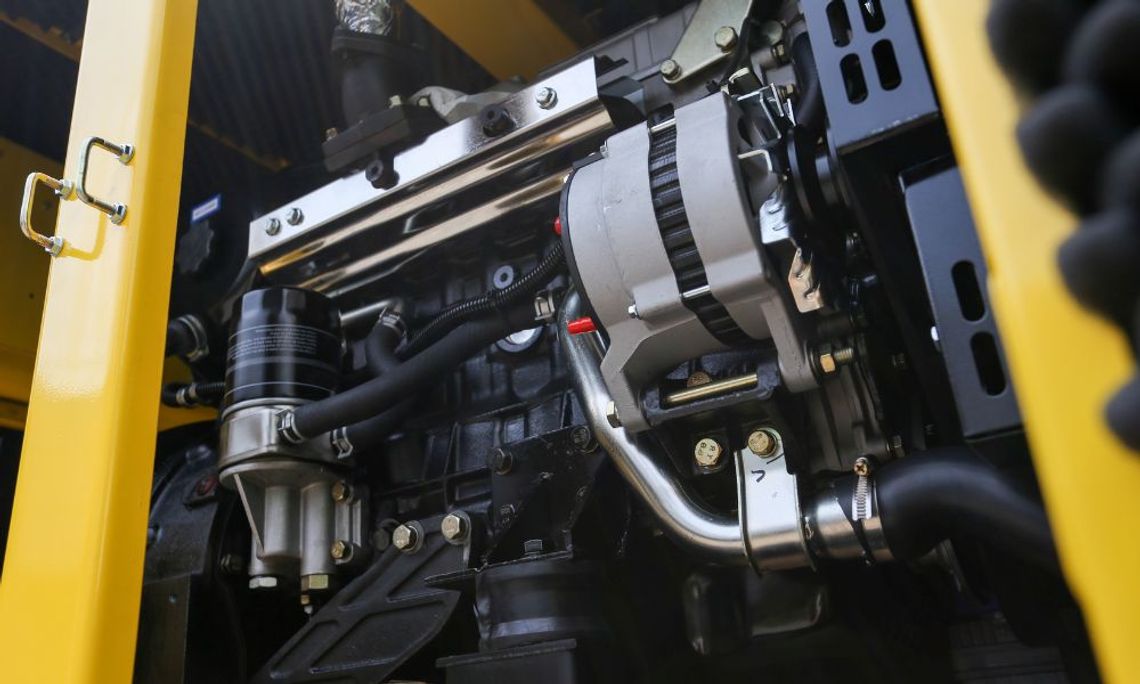

As an expected result of low coolant levels and system failures, hoses and drive belts within power units can become tattered and worn, ultimately overheating equipment. Inspecting parts regularly to ensure proper function and ideal tension is crucial.

Remember to examine the radiator core for accumulated dust and debris from contaminated coolant and corrosion. It would be best to avoid making aftermarket upgrades to machinery to avoid installing inadequate parts that can’t regulate the generator’s temperature.

Fuel Contamination

Diesel and water don’t typically mix well in most fuel-dependent equipment. It would help to keep water away from your generator’s engine, as the smallest amount can significantly impact its performance.

Consider plugging fuel filters to flush out lines and eliminate stagnant water in your generator. You'll also want to use fuel stabilizers to protect diesel from water. Remember to check fuel for discoloration and abnormalities to determine whether trace metals and other particulate is present in storage tanks.

Most industries need backup generators and consider them smart investments, given their ability to keep daily operations running smoothly and efficiently.

But when you forget to upkeep maintenance schedules and service opportunities, you can unknowingly contribute to an untimely system failure. Knowing the reasons why commercial generators fail can allow you to take actionable steps to prevent defects in your equipment.

Comment

Comments