Ensure safety when working with beveling tools. These powerful tools prepare materials for welding or finishing edges but can pose significant risks if you don’t handle them correctly. In the industry, the sharp precision that beveling tools bring to metalwork is invaluable. However, without adhering to strict safety measures, operators may face severe injuries.

Let's look at four important safety tips for using beveling tools and keeping ourselves and our colleagues safe on the job.

Read the User Manual Carefully

Before using a beveling tool, you must familiarize yourself with its features and functions by reading the user manual from the manufacturer. This step includes understanding its power source, RPM (rotations per minute), blade size and type, safety mechanisms, and maintenance instructions. Neglecting to read the manual thoroughly may result in improper use or malfunctioning, leading to accidents and injuries.

Wear Personal Protective Equipment (PPE)

When operating a beveling tool, you need to wear the appropriate personal protective equipment (PPE). This equipment includes safety glasses, gloves, earplugs, and a dust mask if necessary. The PPE should fit correctly and be in good condition to provide adequate protection against flying debris, noise, and dust. As most beveling tools produce sparks, it’s also crucial to avoid wearing loose-fitting clothing that may catch fire.

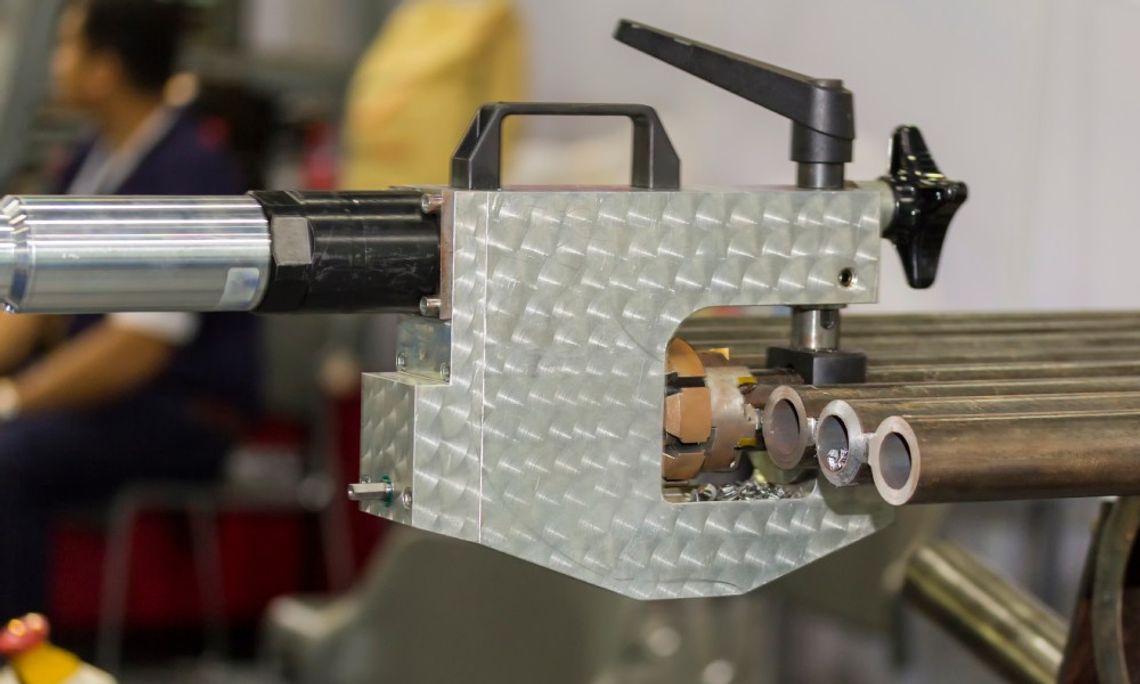

{IMAGE A}

Maintain a Safe Work Area

When using a beveling tool, you should keep the work area clean and organized. This step includes removing any potential hazards, such as clutter, liquids, and other materials that may interfere with the tool's operation. The workspace should also have good ventilation to prevent dust accumulation and ensure proper airflow. Additionally, it’s essential to mark off a safe distance around the work area to prevent others from getting too close and risking injury.

Use Proper Technique

Using a beveling tool requires proper technique to ensure safety and accuracy. This step includes holding the tool with both hands, keeping fingers away from moving parts, and using a stable work surface. Avoid distractions while operating the tool, and focus on the task at hand. If possible, have someone assist or supervise when using a beveling tool.

Working with beveling tools can be an efficient process when you adhere to these four important safety tips. There are many essential tools for tube and pipe sharing and beveling, and you must choose the right one for the job. By following proper safety measures and using the appropriate equipment, you can ensure a successful and accident-free work experience. Remember—safety always comes first when working with any type of machinery or tools.

Comment

Comments